BLUE ENERGY TECHNOLOGY™

a bridge to sustainability

Technology

Moving

Forward

Jupiter Oxygen’s patented high flame temperature oxy-fuel combustion system is part of a new set of cleaner fossil energy technology that has emerged to act as a bridge from conventional fossil fuels to abundant clean and sustainable forms of energy.

How it Works

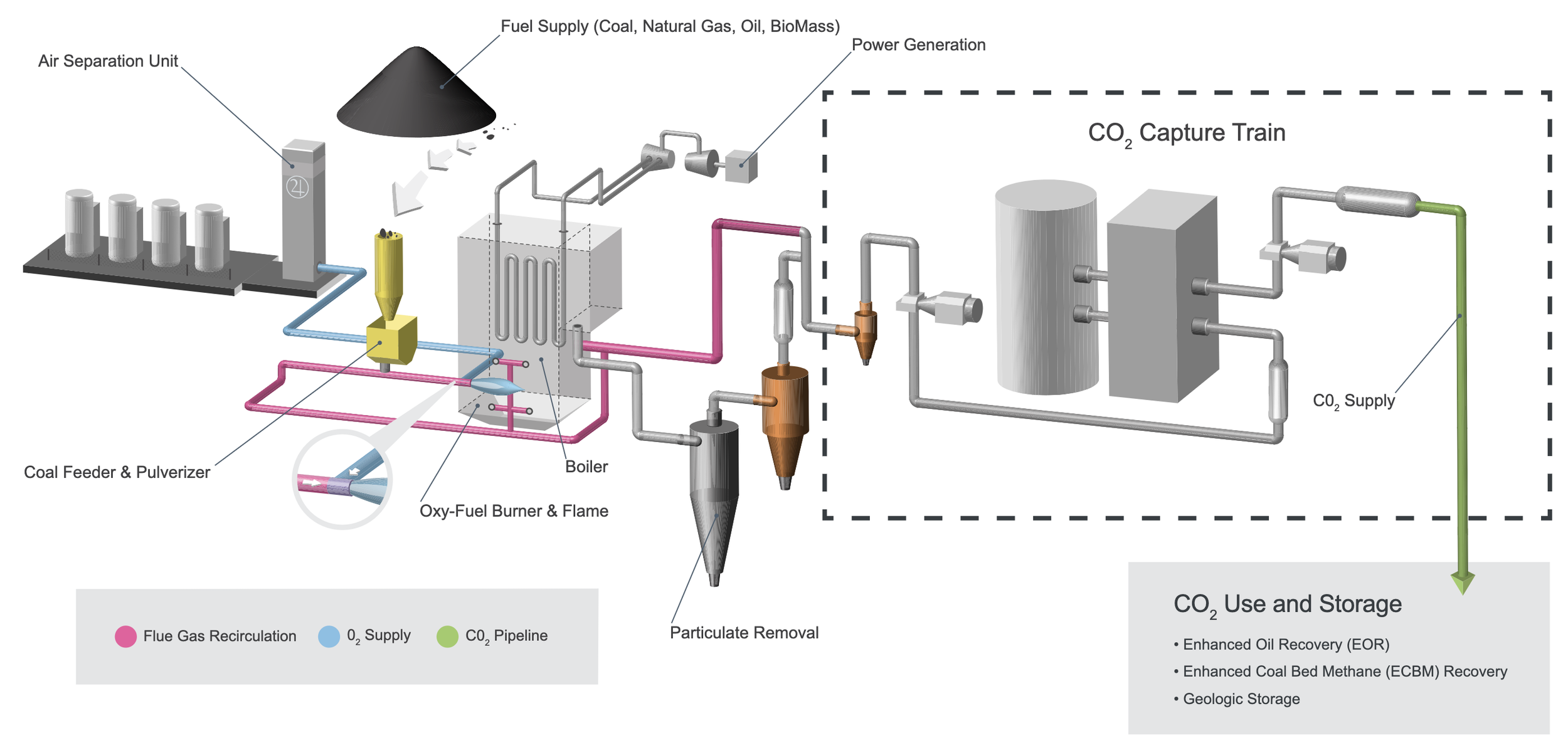

Jupiter Oxygen Corporation's patented fossil fuel combustion technology uses a high temperature flame with 95% to 100% pure oxygen for combustion. In using near pure oxygen over ambient air, it is void of airborne nitrogen. As nitrogen uses energy during combustion, in eliminating it from the process, it increases the amount of energy available to be transferred to the water tubes for the making of steam. Alongside this, in burning the oxy-coal flame at a much higher temperature, it generates far more radiant energy transfer than an air-coal flame [also true using other fuels]. Radiant heat transfer is far more efficient than convective heat transfer. (Note that the higher flame temperature can be safely used for power plant retrofits with existing materials and existing process temperatures). Furthermore, Jupiter's combustion technology operates at or very close to stoichiometry and creates longer residence times. This means that not only is there a more efficient burn of the fuel, but there is more time for the energy generated to be absorbed as the heated gas passes through the boiler.

Process & Innovation

Jupiter Oxygen Corporation has developed a proprietary patented oxy-fueled combustion method applied to power generation boilers. Jupiter's Oxy-Fuel Combustion Process employs a relatively simple concept in which substantially pure oxygen for the combustion process(in the absence of air) is used to oxidize the fuel. There are several important advantages of using an oxygen gas mixture other than air :

Lack of Nitrogen in the gas mixture reduces NOx

Increased O2 content reduces the mass of combustion products

Recirculation of flue gas offers the potential to recover heat otherwise lost up the stack

O2 content can be adjusted to change the Flame Temperature and control Radiant Heat Transfer.

Jupiter Oxygen’s patented oxy-fuel combustion system is capable of economically generating power from coal with ultra-low emissions and increased boiler efficiency. Jupiter’s system uses pure oxygen as the combustion agent, excluding air and thus nitrogen, concentrating CO₂ and pollutants for efficient capture with near zero production of Nitrous Oxides, reducing exhaust mass flow, and increasing radiant heat transfer. Flue-gas recirculation rates can be varied to add flexibility to new boiler designs using this technology.

Power plants operate at design steam temperatures & pressures & significant deviations from those design conditions can damage the equipment in the steam loop such as turbines & feedwater heaters. Modeling combustion under high-oxygen conditions indicates that increased flame temperatures will result, with a concurrent increase in radiant heat transfer in the boiler. Since the oxygen content of the gas supporting combustion has a direct effect on the flame temperature, it presents opportunities to ‘tune’ the flame temperature for the particular boiler system involved by varying the amount of recycled flue gas to regulate heat transfer. The significantly different heat transfer properties of flue gas, which comprises carbon dioxide, water vapor, & oxygen rather than air which is composed predominantly of nitrogen & oxygen are taken into account. The specific impact of such a system on thermal efficiency & power output is sensitive to the arrangement & relative size of heat transfer surfaces in the particular power plant being modeled.

Power Generation System

Applications

Jupiter Oxygen’s High Flame Temperature Oxy-Fuel Combustion technology development has achieved a significant reduction in fossil fuel usage with a focus on energy efficiency and emission benefits within the following industries:

Power Plants

Waste Transformation

Industrial Boilers & Furnaces

Jupiter Oxygen's mission is to promote these energy saving and greenhouse gas avoidance techniques throughout the industry, paying particular attention to high energy intensive businesses. Due to the fuel efficiency of Jupiter’s oxy-combustion carbon capture technology, it has proven to be both financially and environmentally sustainable.

-

Jupiter Oxygen's patented technology development–using a high flame temperature oxy-fuel combustion process for maximizing heat transfer in industrial furnaces and boilers–results in ultra low levels of key pollutants while removing the barriers for carbon capture. The technology provides the pathway for an environmentally friendly and economically sound power plant policy.

-

Unique Approach

Undiluted high flame temperature

Maximized heat transfer effectiveness

Improved efficiency of burner and boiler

Advanced flame stability

Achieved fuel & Cost Savings

Jupiter Oxygen's approach avoids the replication of an air-fired equivalency through the introduction of recycled flue gas into the oxygen stream to the burner, that :

Reduces flame temperature, thus reducing radiation quality and quantity

Results in less energy available for heat transfer in the boiler

-

Economic and Environmental Solutions

Jupiter Oxygen's patented Clean Coal technology provides economic and environmental solutions for existing coal fired power plants resulting in near zero emissions

97+% capture of CO₂

The removal of key pollutants such as NOx, SOx, mercury and particulate matter (PM).

No Air. No Nitrogen - Ultra Low Nitrous Oxides without costly back-end control

Less Fuel used to produce steam

Flue Gas exhaust from the Boiler is 1/4 of Air-Fired

Brownfield permitting is quick and easy

NIMBY-ism isn’t an issue

Local grid faces no disruption – tie-in is unchanged

Local communities are happy to maintain facilities

Cuts CO2 emissions by 97%+ (and even Net-Negative CO2 emissions when co-firing with biomass)